We offer a wide range of structural designs to fit your product and retail requirements.

Build a display that merchandisers can deploy quickly, keep stocked, and remove cleanly after the campaign.

Strategic advantages for high-impact retail marketing

Pallet displays create a commanding retail presence that stands out in high-traffic areas. Large-format graphics visible from across the store drive customer engagement and significantly increase brand awareness.

Retailers report 200-400% sales increases compared to standard shelf placement. Pallet displays position products at optimal eye level while encouraging bulk purchases through impressive product presentation.

Full pallet displays hold substantial inventory, reducing restocking frequency and labor costs. Quarter and half pallet options provide flexibility for different retail environments and product volumes.

Pallet displays simplify logistics for retailers by combining product and display in one shipment. Pre-filled options eliminate store labor for setup, increasing retailer acceptance rates significantly.

Lower per-unit cost than permanent fixtures with higher ROI. Temporary nature allows frequent updates for new campaigns without major investment, keeping your marketing fresh and relevant.

Position displays in high-traffic zones like store entrances, main aisles, and seasonal areas. Create impressive product presentations that naturally draw customers and encourage exploration.

Your Trusted Manufacturing Partner in China

At Kingwin Paper, we specialize in designing, manufacturing, and distributing custom corrugated cardboard floor displays for global retail environments. Based in Shenzhen, China, we offer global clients factory-direct pricing without compromising on quality.

Our displays are designed to position your products at eye level with vivid, custom-designed imagery that attracts and retains customer interest. Whether you need a simple bin or a complex structural masterpiece, our engineering team brings your vision to life.

As a leading manufacturer based in Shenzhen, China, we provide integrated design, manufacturing, and distribution services, delivering high-quality custom solutions for retail environments.

Located in Shenzhen, we handle everything under one roof: Prototyping, design, printing, manufacturing, and distribution. No outsourcing means better quality control and lower costs.

We invest in direct-to-corrugate High Speed Digital Printing, alongside traditional Lithography and Flexography. This allows for vibrant graphics, shorter lead times, and cost-effective short runs.

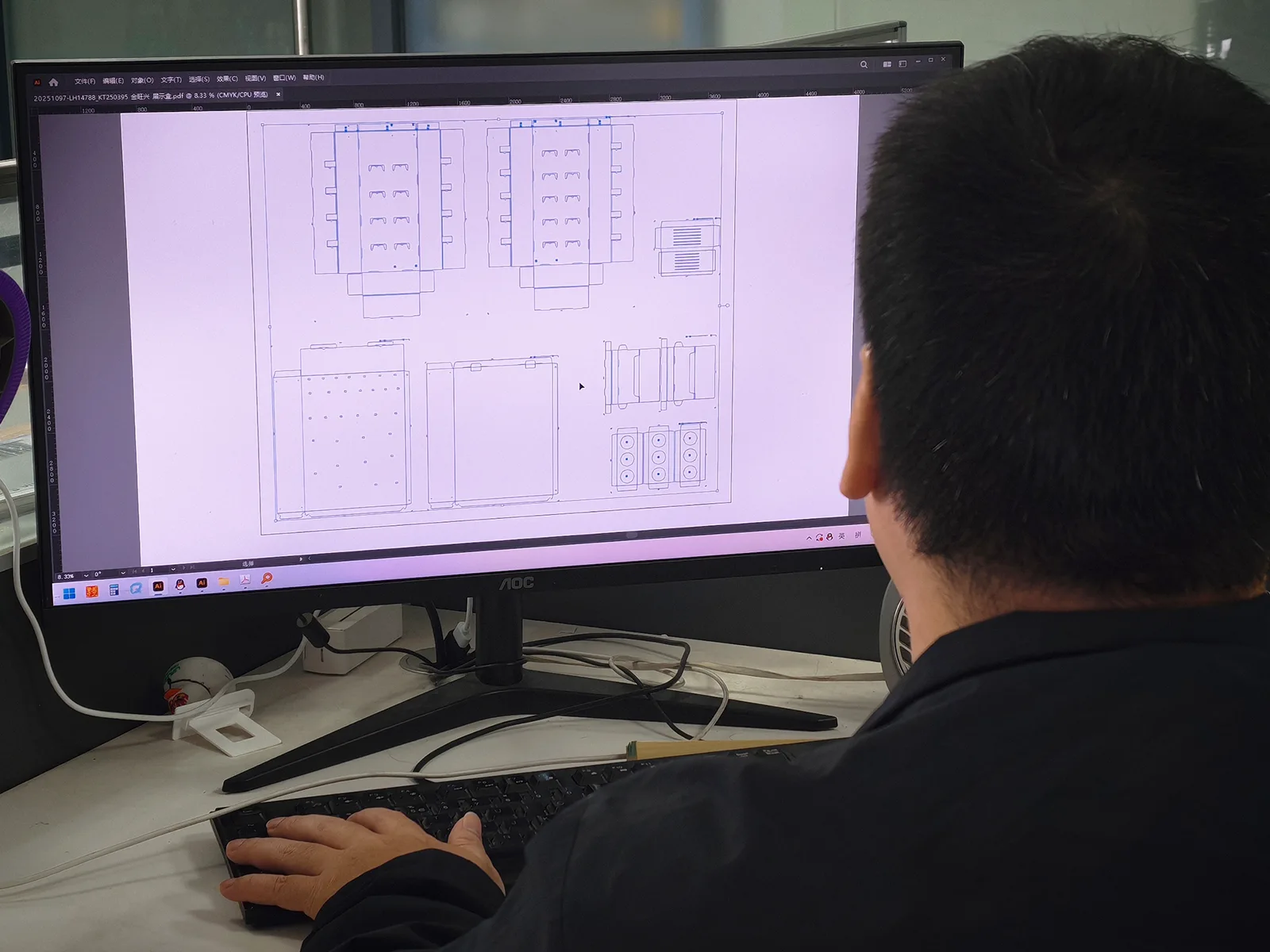

Our experienced design team turns your doodles into reality. We ensure your displays are "Retailer Compliant", meeting strict guidelines for size, weight, and durability for major retail chains.

Sustainability is key. Our displays are made from 100% recyclable corrugated cardboard containing 60% to 95% post-consumer waste.

We offer flexible packing options: flat packed, pre-assembled, or pre-filled with your products (co-packing) to save you time and labor at the retail level.

With years of export experience, we understand international logistics. We ensure your custom displays arrive safely and on time, anywhere in the world.

From concept to completion, we guide you every step of the way

We understand your vision and retail requirements.

Structural design and 3D rendering for approval.

White sample for structure & print proof for color.

High-quality production in our Shenzhen factory.

Assembly, packing, and global shipping.

Detailed capabilities and standards

Full: 48"×40" (1219×1016mm) | Half: 24"×40" or 48"×20" | Quarter: 24"×20"

Custom dimensions available to meet specific requirements

Standard: 48"-72" (1219-1829mm)

Custom heights available up to 96" (2438mm) with structural reinforcement

Quarter Pallet: Up to 150kg | Half Pallet: Up to 300kg | Full Pallet: Up to 500kg

Load tested and certified for safety compliance

B-Flute (3mm), C-Flute (4mm), BC-Flute (double wall 7mm)

125# to 275# test strength options for different load requirements

Lithography: Highest quality, 150+ LPI

Flexography: Cost-effective, durable

Digital: No plates, full CMYK, variable data capable

Aqueous coating, UV coating, lamination (gloss/matte), spot UV, embossing, die-cutting (standard/laser), perforations, scoring for assembly

Flat-pack (most economical), Pre-assembled (ready to fill), Pre-filled (ship to store), Tool-free assembly designs available

FSC certified materials, Retailer-specific standards (Walmart, Target, Costco, etc.)

Pallet displays succeed when structure, board grade, printing, and packing work together.

Common questions about pallet display manufacturing

Expert insights for successful retail campaigns

Successful pallet displays combine strategic placement with compelling design. Position displays at store entrances or main aisle intersections where foot traffic is highest. Studies show displays in these locations generate 3-4 times more sales than standard shelf placement. Time campaigns with seasonal peaks, product launches, or promotional periods when customer purchase intent is highest. The temporary nature of cardboard displays allows brands to refresh messaging frequently, maintaining customer interest throughout extended campaigns.

Proper structural design is critical for pallet display success. Weight distribution must be carefully calculated to prevent tipping or collapse. Bottom-heavy designs with reinforced bases provide optimal stability. Consider product dimensions and weight when specifying board grade. Heavier products require double-wall corrugated board, while lighter items work well with single-wall. Our engineering team uses computer-aided stress testing to validate designs before production, ensuring displays safely support products throughout their retail life while maintaining visual appeal.

Corrugated cardboard strength varies significantly by grade and construction. B-flute offers excellent printing surface with moderate strength, ideal for lighter products. C-flute provides superior cushioning and stacking strength for medium-weight items. BC-flute double-wall construction delivers maximum strength for heavy products up to 500kg. Board test ratings indicate compression strength. A 200# test board withstands 200 pounds per square inch before failure. Our team recommends appropriate grades based on your specific product weight and stacking requirements.

Major retailers maintain specific requirements for in-store displays. Walmart requires displays under 72" height with specific structural certifications. Target specifies maximum footprints based on store format. Costco requires pallet displays ship pre-filled with products. Many retailers mandate flame-retardant treatments for safety compliance. Understanding these requirements before design prevents costly rejections. Kingwin Paper maintains current specifications for major retail chains globally, ensuring your displays meet all requirements and gain retailer approval efficiently.

Cardboard pallet displays offer significant environmental benefits over permanent fixtures. Corrugated cardboard contains 60-95% post-consumer recycled content and is 100% recyclable at end of life. This circular approach minimizes environmental impact while meeting retailer sustainability requirements. FSC certification provides third-party verification of responsible forestry practices. The temporary nature of cardboard displays for seasonal campaigns reduces overall material consumption compared to permanent fixtures that become obsolete when campaigns change. Many retailers actively seek sustainable display solutions.

Effective pallet display design balances visual impact with structural requirements. Use high-contrast colors and large typography visible from 20+ feet away. Graphics should communicate key messages within 3 seconds as customers pass by. Include clear product information and pricing at multiple viewing angles. Header cards extending above typical sightlines increase visibility across the store. Consider shopper behavior patterns. Customers approach from multiple directions, so design graphics for 360-degree visibility. Work with experienced designers who understand both graphic design and structural engineering for optimal results.