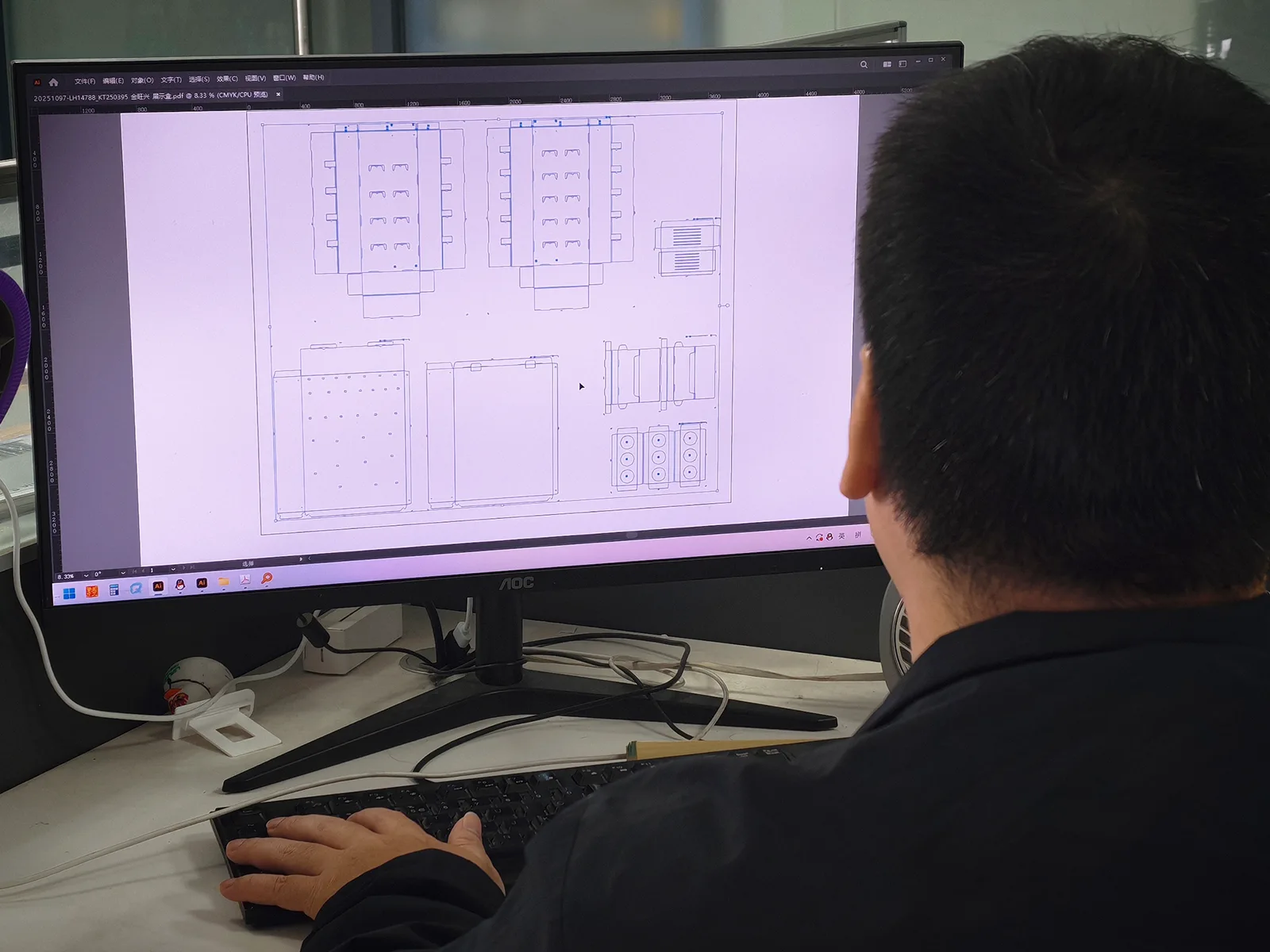

We offer a wide range of structural designs to fit your product and retail requirements.

Your Trusted Manufacturing Partner in China

At Kingwin Paper, we specialize in designing, manufacturing, and distributing custom corrugated cardboard floor displays for global retail environments. Based in Shenzhen, China, we offer global clients factory-direct pricing without compromising on quality.

Our displays are designed to position your products at eye level with vivid, custom-designed imagery that attracts and retains customer interest. Whether you need a simple bin or a complex structural masterpiece, our engineering team brings your vision to life.

As a leading manufacturer based in Shenzhen, China, we provide integrated design, manufacturing, and distribution services, delivering high-quality custom solutions for retail environments.

Located in Shenzhen, we handle everything under one roof: Prototyping, design, printing, manufacturing, and distribution. No outsourcing means better quality control and lower costs.

We invest in direct-to-corrugate High Speed Digital Printing, alongside traditional Lithography and Flexography. This allows for vibrant graphics, shorter lead times, and cost-effective short runs.

Our experienced design team turns your doodles into reality. We ensure your displays are "Retailer Compliant", meeting strict guidelines for size, weight, and durability for major retail chains.

Sustainability is key. Our displays are made from 100% recyclable corrugated cardboard containing 60% to 95% post-consumer waste.

We offer flexible packing options: flat packed, pre-assembled, or pre-filled with your products (co-packing) to save you time and labor at the retail level.

With years of export experience, we understand international logistics. We ensure your custom displays arrive safely and on time, anywhere in the world.

From concept to completion, we guide you every step of the way

We understand your vision and retail requirements.

Structural design and 3D rendering for approval.

White sample for structure & print proof for color.

High-quality production in our Shenzhen factory.

Assembly, packing, and global shipping.

Strategic advantages for point-of-purchase marketing

Counter displays at checkout areas capture customers during their final purchase decision, increasing impulse buys by up to 400% compared to shelf placement.

Compact footprint maximizes valuable counter space. Perfect for small retail environments where every square inch counts.

Products positioned at eye level during checkout create maximum exposure. Customers spend an average of 3-5 minutes in checkout lines.

Lower cost than permanent fixtures with higher ROI. Easy to update for new campaigns without significant investment.

Pre-assembled or easy-assembly designs allow retailers to set up displays in minutes. No tools required for most configurations.

Perfect for seasonal promotions, product launches, and limited-time offers. Replace easily as campaigns change.

Common Questions from Our Partners

Expert Insights on Cardboard Counter Displays

Counter display units are compact POP (point-of-purchase) displays designed for placement on retail counters, checkout areas, or service desks. They maximize impulse purchases by positioning products at eye-level during customer transactions. CDUs typically hold 12-48 units and measure 12-18 inches in height.

E-Flute (1.5mm): Best for lightweight counter displays with superior print quality

B-Flute (3mm): Standard choice balancing strength and printability

EB-Flute (4.5mm): Double-wall construction for floor displays supporting heavy products

Our experts recommend flute type based on your product weight, display size, and retail environment.

Visibility: Header cards should be 8-12 inches tall with bold branding

Accessibility: Product access from front or top without obstruction

Stability: Base width minimum 70% of height for freestanding displays

Graphics: 300 DPI resolution, CMYK or Pantone PMS colors, die-cut windows for product visibility

Offset Lithography: Highest quality for complex graphics (MOQ 1000+)

Flexography: Cost-effective for simple designs (MOQ 500+)

Digital Printing: Low-volume runs with fast turnaround (MOQ 100+)

Finishes: Gloss/matte varnish, spot UV, aqueous coating, lamination for durability and visual impact

Kingwin Paper displays are engineered for 3-12 month retail cycles depending on environment and handling. Our B-flute constructions withstand 200+ customer interactions. Moisture-resistant coatings extend lifespan in refrigerated or outdoor environments. Structural testing ensures displays maintain integrity throughout promotional campaigns.

Step 1 - Inquiry & Quotation (24 hours): Share product specs, quantity, design requirements

Step 2 - Design & Dieline (3-5 days): Our team creates structural design and artwork layout

Step 3 - Sample Production (7-10 days): Physical prototype for approval and testing

Step 4 - Mass Production (15-20 days): After sample confirmation and deposit payment

Step 5 - Quality Control & Shipping (5-7 days): Inspection, packaging, and export documentation